Hydrostatic Transmission (HST) System

Hydrostatic Transmission system provides smooth and efficient power transmission by connecting the hydraulic pump and motor in a closed circuit. This system is widely used for the traveling function of many construction machinery and agricultural machines.

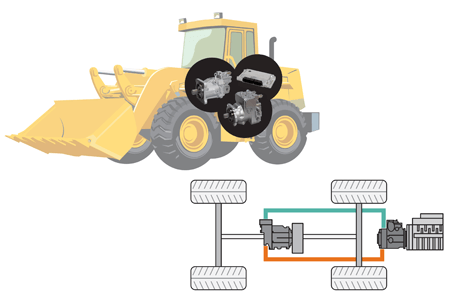

The Hydrostatic Transmission (HST) System can be utilized on the applications that require high torque output at low driving speed or repeat reversing direction such as the wheel loaders, dozers, telehandlers, or combine harvesters and enables smooth driving speed adjustment without operating the gear shift.

Utilizing the closed loop axial piston pump K8V series pumps and the high-speed swash plate type axial piston motor M7V series in the closed circuit, highly efficient and powerful driving performance and smooth driving feeling can be achieved.

Saving the Fuel for the Machine Operation

The combination of highly efficient hydraulic components and an electronic controller that provide the optimum performance can contribute to the fuel saving of the machine.

Open Circuit vs Closed Circuit

Hydraulic pumps that provide the energy to drive motors and cylinders through hydraulic pressure come in two types: one for an open circuit, and the other for a closed circuit. While hydraulic excavators employ an open-circuit system, a continuously variable hydrostatic transmission (HST) consists of a closed-circuit system.

The biggest market for closed-circuit hydraulic equipment is industrial vehicles provided with an HST drive system, which include wheel loaders, tractors, and forklifts. As such, motors used in a closed-circuit system require high speed and high torque capabilities, as well as a pump for generating force.

-

Specifications

- - collapse all

Performance Characteristics

Pumps - - Kawasaki K8V Series - - Displacement (cm³) 71 - 130 Pressure (Mpa) 40 - - Control Type - - Electric flow control - Hydraulic pilot flow control - - Motors - - Kawasaki M7V / M7X Series - - Displacement (cm³) 85 - 160 Output Torque 541 - 1019 Speed 3100 - 3900 (at max displacement) Features and Benefits

Kawasaki K8V Pumps Supply hydraulic fluid at a pressure of 40 MPa. They not only boast the world’s top-level pump efficiency, but also achieve low noise and high reliability, responding to the needs of industrial vehicles - Kawasaki M7V Motors Receive the force of hydraulic pressure generated by a K8V pump to produce high speed and high torque. Compared to a motor for hydraulic excavators, which is capable of operating at approximately 2,000 rpm, a motor for HST can run at 5,000 rpm, nearly doubling the power density (power per unit weight) - Markets

Industrial - Mobile - Forestry - Agriculture - Material Handling - Applications

Wheel Loaders - Tractors - Fork Lifts - -

Market Applications

-

Resources

Can't find what you are looking for or need more information? Contact us

-

Request Information