This is Parker | Using a Mobile Display as a Dynamic Numeric Keypad Input Device

Control of Vehicle Speed is Important to Equipment Operators.

Posted by Hydraulics Team on Monday, July 30, 2018

GS Global Resources is proud to be affiliated with Parker.

The ability to accurately set the speed of a conveyor or roller in applications such as road paving or striping, crop sprayers, and sugar cane harvesters is essential to help optimize productivity and help reduce waste. Additionally, the ability to enter a user ID, PIN or password is often a requirement to help ensure only authorized users to have access to operating heavy equipment. Although large, more complex displays can perform these basic functions, they are often not cost-effective or small enough to be a good application fit.

A cost-effective, dynamic solution

The Parker PHD28 touchscreen display offers a cost-effective replacement for a traditional, robust keypad in a dynamically configurable platform. In addition, the PHD28 has enough built-in processing power to perform basic calculations, check entry limits of values entered, rescale values or even change the value based on an incoming CAN message or input signal. With its compact, 2.8-inch size, it fits well in many consoles and dashboards without compromising valuable space. PHD28 used in conjunction with other Parker electronic products creates a simple to use number entry system that can control complicated systems.

Numerical entry to control vehicle speed

When control of conveyor speed is needed to perform the functions of the vehicle, a PHD along with an IQAN controller can provide this functionality as a low cost and efficient solution.

For example, the Parker PHD28 programmed as a numeric keypad will allow the operator to select the desired conveyor speed and then transmit that value to an IQAN MC43 controller to control the vehicle. This instance can be expanded to any of the PHD family displays as well as the IQAN family of controllers.

In this example, a value is entered by the user and if within range, the target speed is transmitted over the CAN-bus to the IQAN controller. To confirm the value, the feedback from the IQAN controller is shown in the top right of the screen and is used to control the vehicle speed.

The IQAN controller can then communicate with the diesel engine and brake control system to regulate vehicle speed. When vehicle speed does not match the input value from the keypad, the IQAN controller can notify the engine to speed up if the vehicle is moving too slow. If the vehicle is moving too fast, the IQAN controller can activate the brake system so the vehicle will slow down.

Vehicle speed can be measured using a sensor such as a Parker GS60 speed sensor. The frequency output from the GS60 can be connected to the IQAN controller, which would use a PID loop to control the engine and braking system to maintain the desired speed.

If an operator must adjust vehicle speed, they can enter the appropriate speed value or use the up and down arrows to adjust the current value.

Parker offers the keypad program for the PHD eliminating the need for programming in this specific configuration. An IQAN 5 external function and example application is also supplied to make it easy to integrate with the rest of the IQAN application. If a custom design or look is desired, the PHD28 can be programmed to fit that application using Crank Storyboard software.

In the example to the right, the screen shows a numerical keypad where the user can enter a numerical value with 0.1 precision. The user enters the value and then has the option to select cancel, revert to the previous value, or enter to accept the value. Upon acceptance, the value is then transmitted to the system controller via a J1939 message. The user also has the option to increment and decrement the current value using the up and down arrows.

This example is configured so that the system controller can send an acceptable maximum value as a variable to the PHD to qualify the input value is within range. Then the PHD gives a color-coded visual indication to the user the value was accepted. In the example above, the screen shows a numerical keypad where the user can enter a numerical value with 0.1 precision. The user enters the value and then has the option to select cancel, revert to the previous value, or enter to accept the value. Upon acceptance, the value is then transmitted to the system controller via a J1939 message. The user also has the option to increment and decrement the current value using the up and down arrows.

The transmitted J1939 message in this example uses PGN 0xFF00 with two parameters: the entered value and a Boolean search that is active while the OK button is pressed. The resulting J1939 message in the example also uses PGN 0xFF00 with two parameters: the maximum acceptable value and a feedback value to the system controller can acknowledge that entered value was accepted. The transmitted J1939 message in this example uses PGN 0xFF00 with two parameters: the entered value and a Boolean search that is active while the OK button is pressed. The resulting J1939 message in the example also uses PGN 0xFF00 with two parameters: the maximum acceptable value and a feedback value so that the system controller can acknowledge that entered value was accepted.

This application example can be used as is for a basic keypad device, can be modified to accommodate desired form and function or can be used in an existing PHD application to add keypad functionality. The example contains the graphical content, screen layout using Crank Storyboard and functionality written in Lua script.

In many cases, the content of the keypad should be adjusted for regional content, customer color theme or operating mode. These dynamic changes cannot be accomplished on a traditional mechanical keypad.

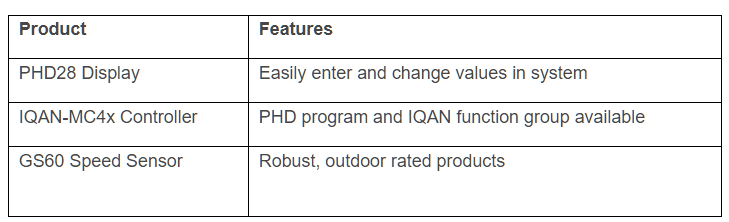

Products and Features:

Article contributed by Edward Polzin, regional application engineer – central, Electronic Controls Division, Parker Hannifin Corporation

GS Global Resources is the Parker IQAN knowledge center for OEMs. We have a strong partnership with Parker ECD, offering Parker Electronic Control products, software, training, and engineered solutions.

Contact us today to learn more.